The Advantages of Using Hermetic Feedthroughs in Harsh Conditions

In today’s rapidly advancing technological landscape, the need for reliable and efficient components in harsh environments is more crucial than ever. Hermetic feedthroughs have emerged as a popular choice for applications in extreme conditions due to their ability to provide airtight seals and protect sensitive components from the elements. In this article, we will explore the various advantages of using hermetic feedthroughs in harsh conditions and why they have become indispensable in industries such as aerospace, oil and gas, and medical devices.

What are Hermetic Feedthroughs?

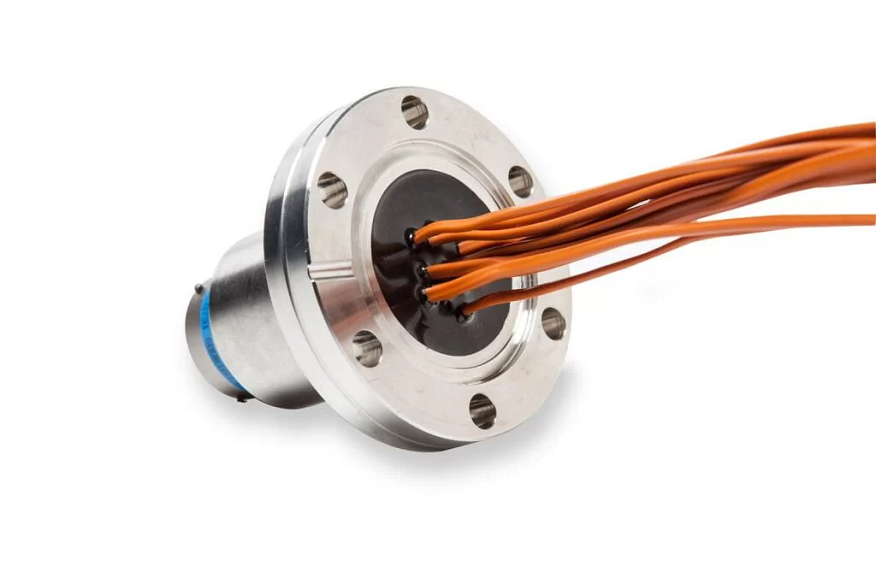

Before diving into the advantages of using hermetic feedthrough, let’s first understand what they are. Hermetic feedthroughs are electrical or optical components that are designed to pass various signals or power through a sealed barrier without compromising the integrity of the enclosure. These feedthroughs are commonly used in applications where airtight seals are required to prevent contamination, moisture, or other harmful elements from entering sensitive equipment.

Advantages of Using Hermetic Feedthroughs in Harsh Conditions

- Reliable Performance: One of the primary advantages of using hermetic feedthroughs in harsh conditions is their reliable performance. These feedthroughs are specifically designed to maintain a hermetic seal, ensuring that no external elements can penetrate the enclosure and damage the sensitive components inside.

- Durability: Hermetic feedthroughs are built to withstand the rigors of harsh environments, making them highly durable and long-lasting. Whether exposed to extreme temperatures, high pressures, or corrosive chemicals, these feedthroughs can continue to function effectively without any degradation in performance.

- Protective Barrier: Hermetic feedthroughs act as a protective barrier between the internal components of a system and the external environment. By creating an airtight seal, these feedthroughs prevent contamination, moisture, and other harmful substances from entering the enclosure and causing damage.

- Versatility: Hermetic feedthroughs come in a variety of shapes, sizes, and configurations, making them highly versatile and adaptable to different applications. Whether you need a feedthrough for high-vacuum systems, underwater equipment, or medical devices, there is a hermetic feedthrough available to meet your specific requirements.

- Cost-Effective: While the initial cost of hermetic feedthroughs may be higher than non-hermetic alternatives, their long-term cost-effectiveness cannot be overstated. By providing a reliable and durable solution for harsh environments, these feedthroughs can help prevent costly downtime and equipment failures in the long run.

- Ease of Installation: Hermetic feedthroughs are designed for easy installation, making them ideal for applications where time and efficiency are critical factors. Whether you are retrofitting existing equipment or designing a new system from scratch, hermetic feedthroughs can be seamlessly integrated to provide the necessary sealing and connectivity.

In conclusion, the advantages of using hermetic feedthroughs in harsh conditions are clear. From their reliable performance and durability to their protective barrier and cost-effectiveness, these feedthroughs offer a range of benefits that make them indispensable in a wide range of industries. Whether you are working in aerospace, oil and gas, or medical devices, incorporating hermetic feedthroughs into your systems can help ensure the longevity and reliability of your equipment in even the harshest environments